Selection Guide

Industrial Carbide Burrs

CARBIDE BURR SELECTION AND USE:

The first step in selecting the proper burr is to pick the best shape and cut style.

The first step in selecting the proper burr is to pick the best shape and cut style.

- Selection of shape and diameter should be based on the work piece, and the operation to be performed.

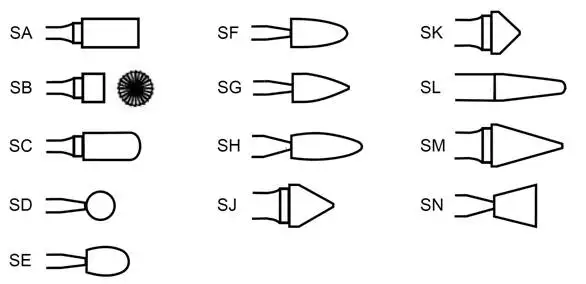

- Burs have 13 basic shapes:

- Burs come in 7 kinds of flute style as following.

6 - Double Cut: Very efficient stock removal. Creates a small chip. Good finish. Excellent operator control.

3 - Single Cut: General purpose fluting. Produces long chips.

1 - Nonferrous: For nonferrous materials. Aggressive stock removal.

3SP - SP Chip Breaker: Provides breakdown in chips. Better control.

4 - Diamond Cut: For heat treated and tough alloy steels where control is important. Creates a powder-like chip. Excellent finish.

2 - Coarse Cut: Provides large flute area for softer ferrous materials. Fast stock removal.

5 -Fine Cut: For general use on hard materials requiring a fine finish.

- Selection of cut would be based on the material, and finish required.

Material 6 3 1 3SP 4 2 5 Aluminum

Brass, Bronze Copper

Carbon Fiber

Fiberglass

Cast Iron

Plastics

Hard Rubber

Steel, 40-55 Rc

Steel, 55-60 Rc

Steel, Carbon

Steel, Nickel Chrome

Steel, Stainless

Steel, Weldments

Titanium

Zinc

The second step in selecting the right tungsten carbide grade.

We have metric size and fractional size for industrial carbide burrs. Meanwhile, we have 3 kinds of different carbide grades named K30, K25, K20 for carbide burrs.

Grade Cobalt HRA HRC Density

(ISO 3369)Transverse rupture strength (ISO 3327) K30 8% 89.3-89.5 74.3-74.6 14.8 2000 K25 7% 89.5-90.5 74.6-77 14.9 2650 K20 6% 90.1-91.5 76.2-78.4 14.7- 15 1800

The third step in selecting the right rotary speed for SYNDENT carbide burr.

These are general speed recommendations that may need to be adjusted for special application

Swipe or scroll to see more information.Material of work-piece RECOMMENDED ROTARY SPEEDr/min (Rotary speed = the below number x1000) Dia 3mm Dia 6mm Dia 8mm Dia 10mm Dia 12mm Dia 16mm Dia 20mm Dia 25mm Steel, cast steel Non-

hardened,non-

heat treated steelsAggressive grinding 60000-

9500032000-

4800024000-

3600019000-

2900016000-

2400012000-

1800010000-

140008000-

11000Fine grinding 48000-

6400024000-

3200018000-

2400014000-

1900012000-

160009000-

120007000-

10006000-

8000Hard non-ferrous metals Aggressive grinding 27000-

3700013000-

1900010000-

140008000-

110007000-

90005000-

70004000-

60003000-

4000Fine grinding 37000-

4800019000-

2400014000-

1800011000-

140009000-

120007000-

90006000-

70004000-

6000Stainless steel (INOX) Rust and acid-resistant steels Aggressive grinding 32000-

4800016000-

2400012000-

1800010000-

140008000-

120006000-

90005000-

70004000-

6000Fine grinding 37000-

4800019000-

2400014000-

1800011000-

140009000-

120007000-

90006000-

70004000-

6000Aggressive grinding 32000-

4800016000-

2400012000-

1800010000-

140008000-

120006000-

90005000-

70004000-

6000Fine grinding 37000-

5300019000-

2700014000-

2000011000-

160009000-

130007000-

110006000-

80004000-

6000Cast iron Grey cast iron, white cast iron Aggressive grinding 60000-

9500032000-

4800024000-

3600019000-

2900016000-

2400012000-

1800010000-

140008000-

11000middle grinding 48000-

6400024000-

3200018000-

2400014000-

1900012000-

160009000-

120007000-

10006000-

8000Fine grinding 53000-

6400027000-

3200020000-

2400016000-

1900013000-

1600010000-

120008000-

100006000-

8000